When it comes to automation, motion control, and robotics, actuators are indispensable components. Actuators provide the necessary force to move or control mechanisms, enabling the automation of numerous processes. Belt-driven actuators and screw-driven actuators are widely used for their ability to convert rotational energy into linear motion, allowing precise control over movement and positioning. However, there are distinct differences in their design, operation, and performance characteristics. Understanding the differences between belt-driven actuators and screw-driven actuators is crucial for selecting the right actuator for your specific needs.

What are Linear Actuators

Linear actuators are mechanical or electromechanical devices that produce linear motion along a straight path and are used to control and move objects in a linear direction. Linear actuators find applications in various industries, including manufacturing, automotive, healthcare, and home automation. These devices offer precise control, reliability, and ease of integration into different systems.

Linear actuators operate based on different principles, but the primary mechanism involves converting rotational motion into linear motion. This is achieved through the use of various components such as screws, gears, belts, or hydraulic systems. The input energy is transformed into linear displacement, allowing the actuator to extend or retract as needed.

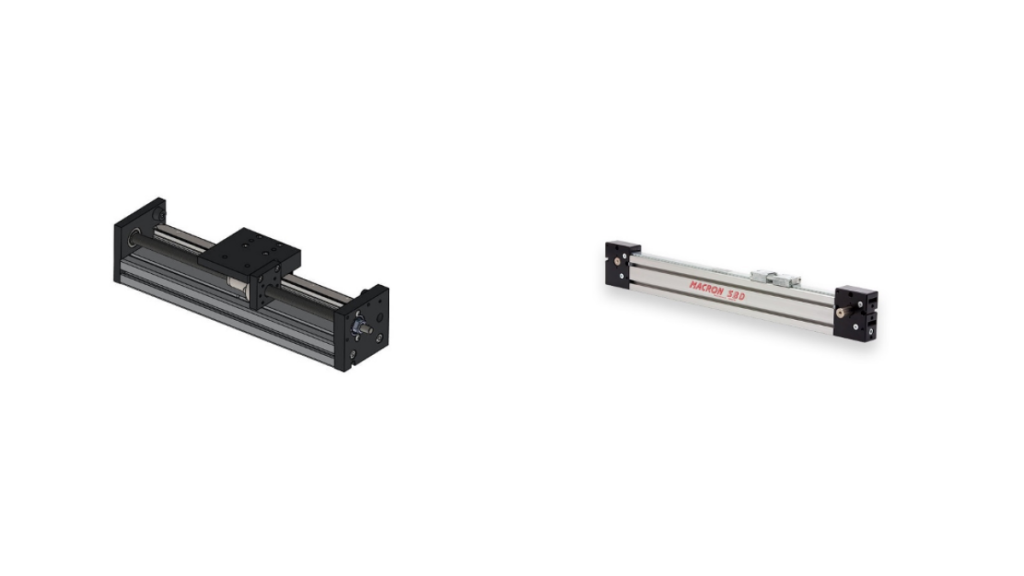

Belt-Driven Actuators

Belt-driven actuators utilize a flexible belt or timing belt to convert rotary motion into linear motion. The belt is typically made of reinforced rubber or polyurethane and is driven by a pulley system. As the belt moves, it translates the rotational force into linear movement, allowing for precise positioning and motion control.

Applications of Belt-Driven Actuators

Belt-driven actuators find applications in various industries, including:

- Robotics and automation systems

- Packaging and material handling equipment

- Printing and labeling machinery

- CNC machines and routers

- Medical and laboratory equipment

Advantages of Belt-Driven Actuators

- High Speed: Belt-driven actuators can achieve high speeds, making them suitable for applications that require rapid linear motion.

- Quiet Operation: The design of belt-driven actuators minimizes noise, making them ideal for environments where noise reduction is essential.

- Cost-Effective: Belt-driven actuators are generally more affordable compared to ball screw actuators, making them a cost-effective solution for many applications.

- Low Maintenance: Belt-driven actuators require minimal maintenance due to their simple design and absence of lubrication requirements.

Disadvantages of Belt-Driven Actuators

- Limited Load Capacity: Belt-driven actuators may have limitations in terms of load capacity, making them less suitable for heavy-duty applications.

- Lower Precision: While belt-driven actuators offer reasonable accuracy, they may not provide the same level of precision as ball screw actuators.

Screw-Driven Actuators

Screw-driven actuators are mechanical devices that convert rotary motion into linear motion using a threaded screw and nut mechanism. They are widely used in applications that require controlled linear movement with high accuracy and repeatability. Screw-driven actuators are known for their ability to provide reliable, efficient, and precise linear motion in a wide range of industries.

The basic working principle of screw-driven actuators involves the rotation of a threaded screw, which moves a nut along its length. As the nut travels along the screw’s threads, it converts the rotary motion into linear motion.

Applications of Ball Screw Actuators

Ball screw actuators are commonly used in the following fields:

- Machine tools and CNC machining centers

- Semiconductor manufacturing

- Aerospace and defense systems

- Automotive manufacturing

- Assembly and inspection equipment

Advantages of Screw-Driven Actuators

- High Load Capacity: Ball screw actuators are known for their high load capacity, making them suitable for heavy-duty applications that require precise positioning and high force.

- Excellent Precision: Ball screw actuators offer exceptional precision, making them ideal for applications that demand accurate and repeatable motion control.

- Long Service Life: With proper maintenance and lubrication, ball screw actuators can have a long service life, providing reliable performance over extended periods.

Disadvantages of Screw-Driven Actuators

- Slower Speed: Compared to belt-driven actuators, ball screw actuators may have limitations in terms of speed, which may not be suitable for applications requiring rapid linear motion.

- Higher Cost: Ball screw actuators are generally more expensive than belt-driven actuators, which can be a determining factor for cost-sensitive projects.

Belt-Driven Actuator vs. Screw-Driven Actuator

When choosing between a belt-driven actuator and a ball screw actuator, several factors should be considered:

- Load Requirements: If your application involves heavy loads, a ball screw actuator may be the better choice due to its higher load capacity.

- Speed Requirements: For high-speed applications, a belt-driven actuator is usually the preferred option.

- Precision and Accuracy: If your application demands precise positioning and accurate motion control, a ball screw actuator provides superior performance.

- Cost Considerations: Budget constraints can influence your decision, as belt-driven actuators are generally more cost-effective than ball screw actuators.

When it comes to linear motion, both belt-driven and screw-driven actuators have their unique advantages and limitations. Consider the specific requirements of your application, including load capacity, speed, precision, and budget, to make an informed decision. Belt-driven actuators are well-suited for high-speed applications with moderate loads, while ball screw actuators excel in precision and heavy-duty applications. Choose the actuator that best aligns with your needs to achieve optimal performance and efficiency.

HVH Industrial Solutions offers a wide range of linear actuators. If you are interested in exploring our extensive range of actuators, please feel free to visit our website at [hvhindustrial.com]. On our website, you will find detailed information about the various types of linear actuators we offer, their specifications, and their applications.