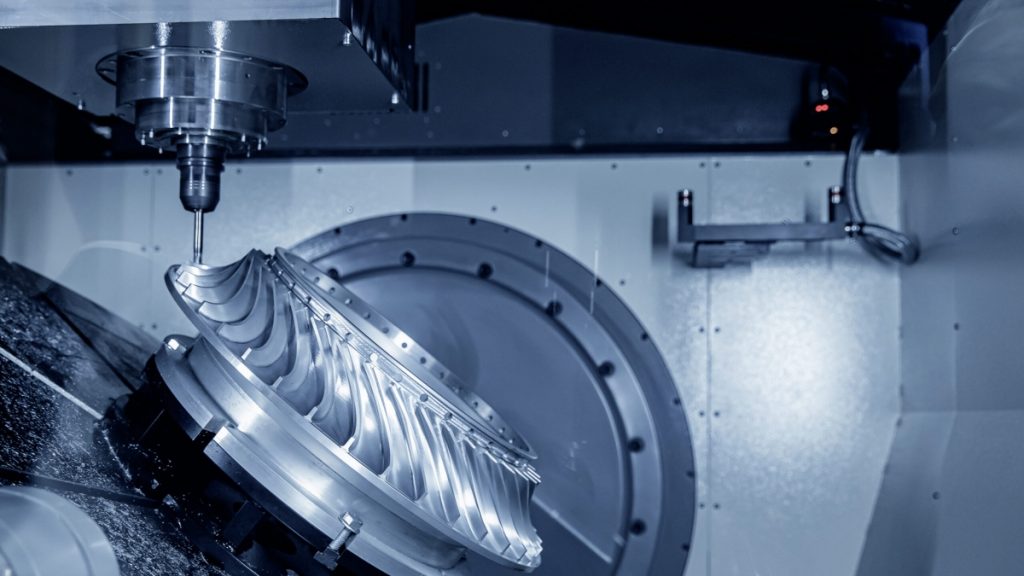

Computer Numerical Control (CNC) machines are pivotal in modern manufacturing, offering precise control over machining processes.

Beyond their technical prowess, CNC machines are playing a critical role in promoting industrial sustainability, a concept essential for reducing environmental impact and conserving resources.

Here’s how CNC technology is advancing sustainability in the industrial sector according to Amastone, leader in the US for selling CNC tools.

1. Reducing Material Waste

CNC machines excel in precision, ensuring that each cut and operation is executed with minimal material waste. Traditional manufacturing methods often result in significant leftover materials, but CNC machines optimize every piece of raw material used, significantly cutting down on waste. This precision helps conserve raw materials and reduces the environmental footprint of manufacturing processes.

2. Optimizing Energy Consumption

Energy efficiency is a very important aspect of sustainable manufacturing. CNC machines are designed to optimize energy use during operations. They run efficiently, using only the necessary amount of energy required for each specific task.

This optimization not only reduces the overall energy consumption but also lowers operational costs, making manufacturing processes more sustainable and economical.

Key benefits of energy optimization include: – Lower operational costs: Reduced energy consumption directly translates to cost savings. – Environmental impact: Decreasing energy use helps lower the carbon footprint of manufacturing. – Enhanced efficiency: Streamlined operations ensure that energy is used where it’s most needed, without wastage.

3. Extending Tool Life

The precise control offered by CNC machines means that tools are used more efficiently and wear out less quickly.

Prolonging the lifespan of tools reduces the frequency of replacements, thereby lowering the demand for new materials and the energy required to produce them. This aspect of CNC machining contributes to a more sustainable approach to manufacturing by minimizing resource consumption.

Advantages of extended tool life include: – Cost savings: Less frequent replacements reduce expenses on new tools. – Resource conservation: Reduced need for new materials helps conserve natural resources. – Decreased downtime: Longer-lasting tools mean less interruption in production for tool changes.

4. Enabling On-Demand Production

CNC technology facilitates on-demand production, eliminating the need for large inventories and reducing storage costs. Manufacturers can produce items as needed, which not only minimizes waste from overproduction but also ensures that products are up-to-date and meet current market demands.

This shift towards just-in-time manufacturing is a significant step towards sustainability, reducing excess production and associated waste.

On-demand production benefits: – Inventory reduction: Lower storage costs and reduced risk of obsolete stock. – Customization: Ability to quickly adapt to specific customer requirements. – Waste minimization: Producing only what is needed helps prevent surplus and associated waste.

5. Recycling and Reusing Materials

CNC machines are adaptable to working with recycled materials, promoting the recycling and reuse of materials in manufacturing processes. By incorporating recycled materials, manufacturers can reduce their dependence on virgin resources and lower their environmental impact. This ability to efficiently process recycled materials underscores the role of CNC technology in fostering a circular economy within the industrial sector.

CNC machines are at the forefront of advancing industrial sustainability. By reducing material waste, optimizing energy consumption, extending tool life, enabling on-demand production, and facilitating the recycling and reuse of materials, CNC technology is transforming manufacturing practices. As industries continue to prioritize sustainability, the integration of CNC machines will be integral in achieving eco-friendly and efficient production processes.