Dessica is an expert in dry air innovation and its modern applications for drying and dehumidification. We have been Developing our insight in the stockpile of imaginative arrangements adjusted to the dry air prerequisites of assembling processes. These arrangements do the hygrometric control of premises, the capacity of items in dry air or to forestall buildup.

Moreover, our system eliminates the issues of obstructing and hardening of pneumatic vehicles, stockpiling storehouses of pounded items. Mostly present in the ago-food, synthetic, drug and seeds stockpiling, its cycles depend on the demonstrated advancements of revolving adsorption silica gel dehydrators.

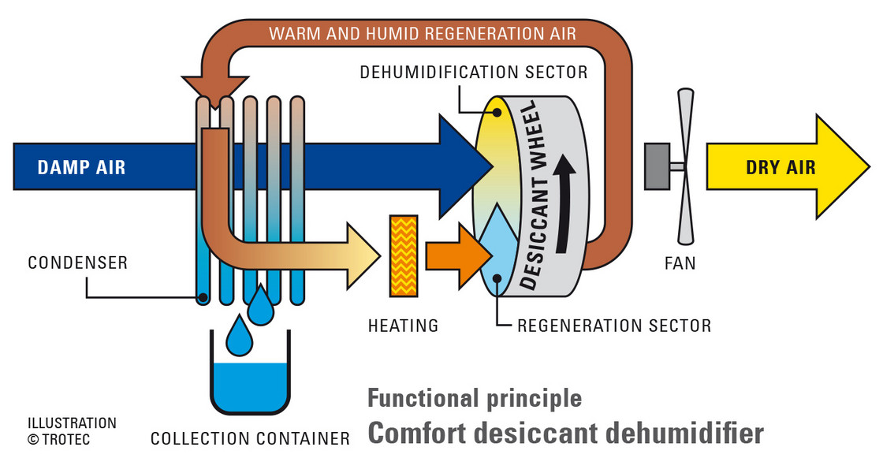

An industrial Desiccant Dehumidifier system eliminates dampness from the air by utilizing a desiccant, a material which effectively draws in and holds water fumes. Desiccant dehumidifiers are particularly appropriate for eliminating dampness from air at a low temperature and low moistness level.

At the core of the dehumidifier is a protected desiccant wheel composed of layered material. Air goes through the flutes of the material, reaching the desiccant. The approaching system airstream emits its dampness to the desiccant. The cycle air is dry as it leaves the wheel. The stickiness loaded wheel pivots gradually into a second, more modest airstream which has been warmed.

Constructional Features Desiccant Dehumidifier:

DESSICA DS system supplies dry air to drying processes, creation processes or again bundling and capacity conditions. They are intended to treat air or be introduced in cools between 5 F and 105 F (- 15 °C and 40 °C). Dominating hygrometry makes it conceivable to control points of interest items or system in industry:

- The packaging has high protection from climatic erosion and made of 1,0 mm tempered steel sheet metal; a few sections made of 1,5- and 2,0-mm treated steel to accomplish inflexibility

- It has minimal plan and low weight of the unit.

- Its elite execution at low temperatures and low relative stickiness in a room.

- Discretionary humidistat is accessible as an extra.

- It has simple admittance to the interior parts of the dehumidifier for the upkeep

- PTC-radiator

- High effectiveness of the launderable silica gel rotor.

- All parts made only by European producers

- the nature of hygroscopic materials

- the improvement of microbes and the spread of miniature living beings

- icing

- the moistness level of structures

- shape

- A few enterprises, for example, drug, food handling, energy, metallurgy and hardware require an exact and high dry air quality, this is what Desiccant dehumidifier system gives to us.

Advantages of an industrial Desiccant Dehumidification:

Modern dehumidification system has become progressively famous lately in light of lower hardware costs accomplished through economies of scale, measured plans, and the utilization of desiccant silica gel wheels. In a unique desiccant system, the reactivation heat was delivered by consuming gaseous petrol. In any case, an all-electric desiccant system is presently accessible. These desiccant systems are incredibly productive and simple in industries in which they utilize dismissed hotness from the condenser to recover the desiccant wheel.

Safety and Hygiene:

The dry air is then absolutely usable. The auxiliary wind stream, called reactivation air, clears the dampness held by the rotor silica gel part.

A piece of the air volume goes through the rotor by the hotness recuperation area, chilling off the drying out material by at the same time raising the air temperature. User health, safety and cleanliness are crucial for Minters and obviously reflected in the plan of the desiccant wheel (rotor). Our rotors are ceaselessly tried freely and have been demonstrated by The Swedish Institute for Food and Biotechnology to have both bactericidal and fungicidal properties.