In the pursuit of manufacturing excellence, achieving precise and efficient adhesive application is paramount. Traditional manual dispensing methods often lead to inconsistencies, waste, and potential quality issues. Enter automated adhesive dispensing systems — a technological solution that’s transforming the way adhesives are applied in various industries, from automotive and electronics to medical devices and packaging.

The Advantages of Automated Adhesive Dispensing

Automated adhesive dispensing systems offer a multitude of benefits that can significantly enhance manufacturing processes across various industries. From improved precision and efficiency to enhanced safety and versatility, these systems are revolutionizing the way adhesives are applied. Let’s explore some of the key advantages.

Unmatched Precision and Accuracy

Automated dispensing systems excel in this regard, offering a level of accuracy and control that surpasses manual methods. This translates to significant advantages for manufacturers.

- Pinpoint Accuracy: Automated dispensing systems utilize advanced technologies, such as robotic arms and precision nozzles, to deliver adhesives with exceptional accuracy. This ensures consistent bead size, placement, and volume, even in complex or intricate applications.

- Reduced Waste and Rework: The precise application of adhesives minimizes waste and reduces the need for rework, leading to cost savings and improved resource utilization.

- Enhanced Product Quality: Consistent and accurate adhesive application translates to improved product quality, ensuring reliable bonding and minimizing the risk of defects or failures.

Increased Efficiency and Productivity

Time is money in manufacturing, and automated dispensing systems offer a significant advantage in terms of speed and throughput.

- High-Speed Operation: Automated dispensing systems can operate at significantly higher speeds than manual dispensing, leading to increased production throughput and shorter lead times.

- Continuous Operation: These systems can operate continuously without the need for breaks or rest, maximizing productivity and minimizing downtime.

- Streamlined Processes: Automated dispensing eliminates the need for manual handling and application of adhesives, streamlining production processes and reducing labor costs.

Enhanced Consistency and Reliability

Consistency and reliability are hallmarks of high-quality manufacturing. Automated adhesive dispensing systems excel in delivering these attributes, minimizing variability, and ensuring predictable outcomes.

- Elimination of Human Error: Automated systems remove the variability associated with manual dispensing, ensuring consistent adhesive application across all products. This consistency leads to improved product reliability and reduced warranty claims.

- Process Control: Automated systems offer precise control over dispensing parameters, such as pressure, temperature, and flow rate, ensuring optimal adhesive performance and bond strength.

- Data Tracking and Traceability: Many automated systems can track and record dispensing data, providing valuable insights for quality control and process optimization.

Versatility and Adaptability

- Wide Range of Adhesives: Automated dispensing systems can handle a diverse range of adhesive types and viscosities, making them suitable for various applications and industries.

- Customizable Solutions: These systems can be customized to meet specific application requirements, with options for different nozzle types, dispensing patterns, and programming capabilities.

- Integration with Existing Systems: Automated dispensing systems can be seamlessly integrated into existing production lines, minimizing disruptions and maximizing efficiency.

Improved Safety and Ergonomics

Workplace safety and employee well-being are paramount considerations in any manufacturing environment. Automated adhesive dispensing systems contribute to a safer and more ergonomic workplace by minimizing risks and reducing physical strain.

- Reduced Exposure to Hazards: By automating the dispensing process, workers are less exposed to potentially hazardous adhesives and fumes, creating a safer and healthier working environment.

- Elimination of Repetitive Tasks: Manual adhesive dispensing often involves repetitive motions that can lead to musculoskeletal injuries. Automated systems eliminate these tasks, improving ergonomics and reducing the risk of workplace injuries.

Types of Automated Adhesive Dispensing Systems

Automated adhesive dispensing systems come in various forms, each designed to address specific application needs and adhesive types. Understanding these different system types empowers manufacturers to select the optimal solution for their unique requirements. Let’s explore some of the most common types:

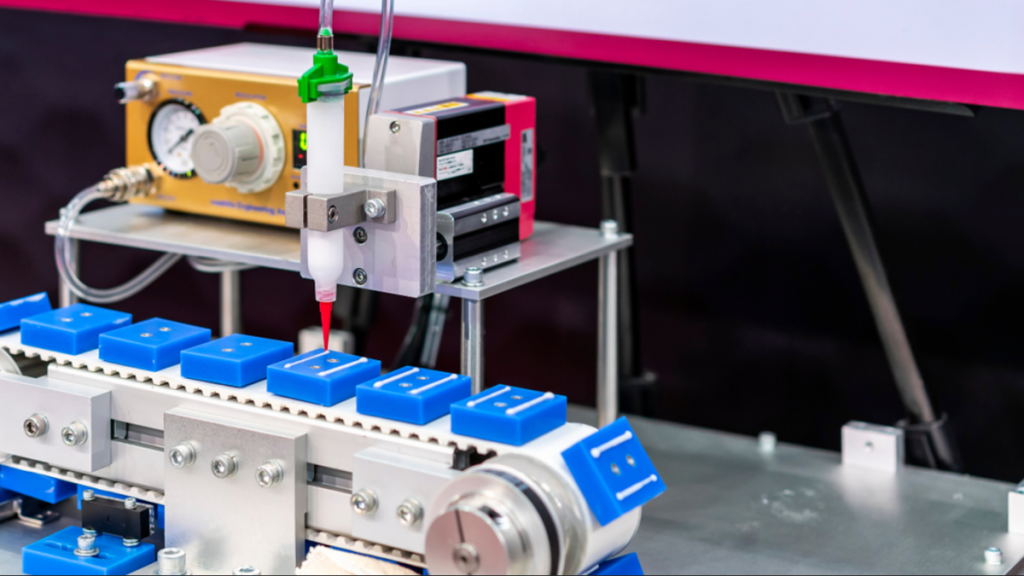

- Robotic Dispensing Systems: These systems utilize robotic arms equipped with dispensing nozzles to apply adhesives with high precision and flexibility.

- Meter-Mix-Dispense Systems: These systems automatically meter, mix, and dispense two-component adhesives, ensuring proper ratios and eliminating manual mixing errors.

- Jetting Systems: These systems use high-pressure jets to dispense adhesives in precise patterns, ideal for applications requiring intricate or complex designs.

- Valve Dispensing Systems: These systems use valves to control the flow of adhesives, providing accurate and repeatable dispensing for various applications.

Applications Across Industries

The versatility and precision of automated adhesive dispensing systems have made them indispensable across a wide range of industries. Here are some of the key sectors where these systems are making a significant impact.

- Cosmetics and Personal Care: Automated adhesive dispensing ensures precise and consistent application of adhesives in the assembly of cosmetic and personal care products, such as lipstick tubes, mascara wands, and perfume bottles.

- Electronics: These systems are crucial for applying adhesives in the assembly of electronic components, including circuit boards, displays, and batteries.

- Food and Beverage: Automated dispensing systems are used for sealing food and beverage packaging, ensuring product freshness and preventing contamination.

- Industrial Manufacturing: From bonding components in machinery and equipment to sealing gaskets and applying coatings, automated adhesive dispensing plays a vital role in various industrial manufacturing processes.

- Paper and Printing: These systems are utilized for precise adhesive application in the production of books, magazines, and other printed materials.

- Plastics: Automated dispensing systems are used for bonding and sealing plastic components in a variety of applications, including automotive parts, medical devices, and consumer products.

Partnering with Automation Experts

Selecting and integrating the right automated adhesive dispensing system requires expertise and careful consideration. Partnering with experienced automation integrators can help ensure a seamless implementation and maximize the benefits of this technology.

A New Era of Adhesive Application

Automated adhesive dispensing systems are ushering in a new era of manufacturing, where precision, efficiency, and reliability are paramount. By delivering consistent, accurate, and controlled adhesive applications, these systems allow businesses to boost product quality, streamline production processes, and build safer working environments. As industries continue to evolve and demands for higher performance and efficiency grow, automated adhesive dispensing will undoubtedly play an increasingly vital role in shaping the future of manufacturing.