Semiconductors are an essential component in the modern digital world, and they form the heart of electronics. Semiconductors are an integral part of all typical home electronic devices such as toys, phones and TVs, and more advanced technology such as rockets and AI. Semiconductors will continue to take a more central role in your day to day activities as the 5G penetrates the world and tech companies align more towards the Internet of Things, IoT.

Here are the necessary basic steps in the production of semiconductors.

The production of semiconductors is a high tech process and capital intensive. The process itself relies heavily on the technology of semiconductors to produce semiconductors. The three primary stages of semiconductors production are;

1. Semiconductor Designing

A Semiconductor is a solid that conducts electricity partially under certain conditions. Semiconductors play an essential role in the production of high tech modern gadgets in the form of microchips. The foundries produce semiconductors in large volumes; hence, a poor design would lead to heavy losses and the production of malfunctioning gadgets. The design stage of semiconductors is therefore very crucial in the production process of semiconductors.

The semiconductor engineers equip themselves with the manufacturer’s standards of the semiconductors. With the knowledge of requirements by the manufacturer and the expectations of the end-user or audience, the design engineer can develop a circuit design. The manufacturer then prints the semiconductor design circuit on wafers. Fabless firms are firms that deal with designing semiconductors.

2. Front-End of Line Semiconductor Fabrication

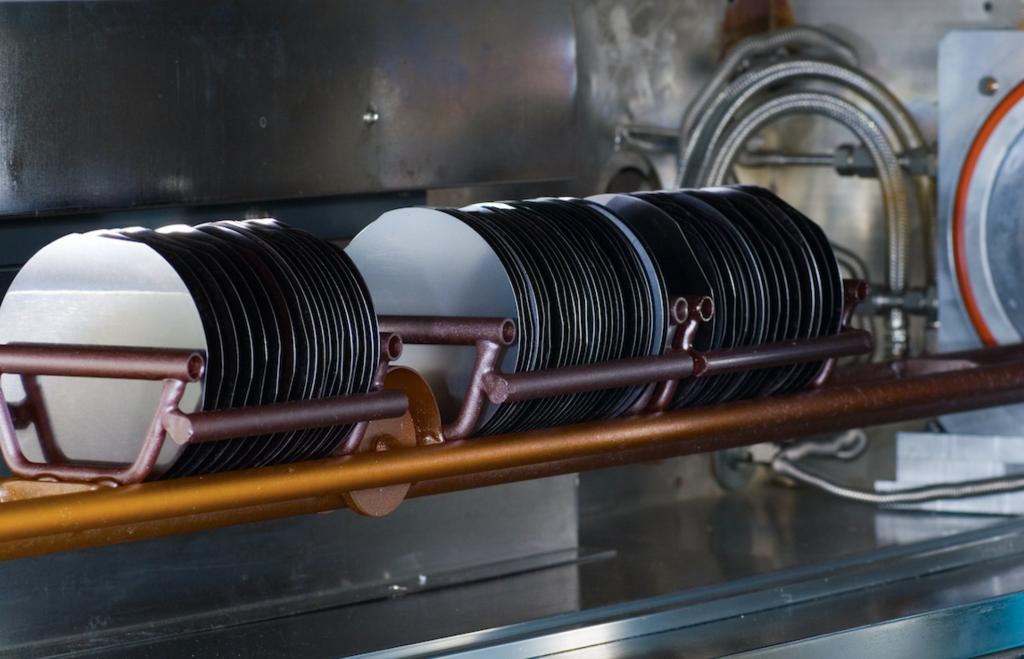

Front-end of line, or FEOL, semiconductor fabrication consists of the physical creation of the semiconductors. The most common component of semiconductors is silicon which is the chemical composition of sand. Silicon undergoes a complex purification process to form ingots. Doping of silicon ingots creates silicon discs with new conductivity properties. The silicon discs then undergo slicing and polishing to make wafers. The manufacture of wafers requires highly sophisticated equipment and materials. The silicon wafers are ultrapure and round. Each silicon wafer can produce thousands of pieces of semiconductors.

3. Back-end of Line Stage

The back-end of the line, also known as BEOL, stage in the manufacture and processing of semiconductors involves assembly, testing, and packaging.

After the FEOL process is complete and the cutting of silicon wafer substrates into individual pieces, the manufacturers transport them to another facility for further processing. Each die of the semiconductor undergoes thorough testing, and the manufacturer separates and discards the defective semiconductors. The semiconductor dies that meet the set standards then undergoes advanced packaging to ensure the safety of the semiconductors, ready for sale.

Applications of Semiconductors

- In-home electronics such as TVs

- High-Speed computing

- Autonomous driving, driverless cars

- 5G technology in Smart devices

- Artificial Intelligence

- Virtual reality

- In-Vehicle Infotainment system

- Collision detection systems

Conclusion

Semiconductors are integrated into different products from different sectors to produce quality gadgets. The demand for advanced semiconductors has increased due to the latest increase in work from home strategies and virtual attendance in meetings, training, and learning. AI and Machine learning, ML, is helping manufacturers of semiconductors in research to increase efficiency. With the application of modern advanced technology in semiconductors, manufacturers are producing efficient and high-quality chips.