In a world where technology meets ingenuity, Omkar Sumbe stands as a paragon of innovation and effective leadership in design and engineering.

The design and engineering sector has long been the backbone of industrial progress, particularly in areas demanding high-level precision, functionality, and safety such as crane manufacturing. With the advent of digital technologies like Artificial Intelligence and IoT, the industry is undergoing rapid transformations, seeking professionals who can navigate this evolving landscape effectively. This makes it not just a field of nuts and bolts, but also of data and algorithms, and it calls for leaders who can harmonize traditional engineering skills with new-age technologies.

Omkar Sumbe is one such dynamic leader in the field of design engineering, particularly within the specialized arena of crane systems. With an impressive career spanning over a decade, Omkar has left an indelible mark on the industry with his forward-thinking approach to engineering solutions. Having worked with leading companies like Advanced Industrial Solutions and Konecranes, he has spearheaded projects that merge functional brilliance with safety considerations. A master of collaboration, Omkar believes in clear communication, shared goals, and utilizing the unique strengths of team members to foster effective teamwork. His unwavering dedication to delivering cutting-edge solutions is exemplified by his development of software enabling instantaneous estimation and drawing generation, streamlining the sales process and greatly enhancing customer engagement.

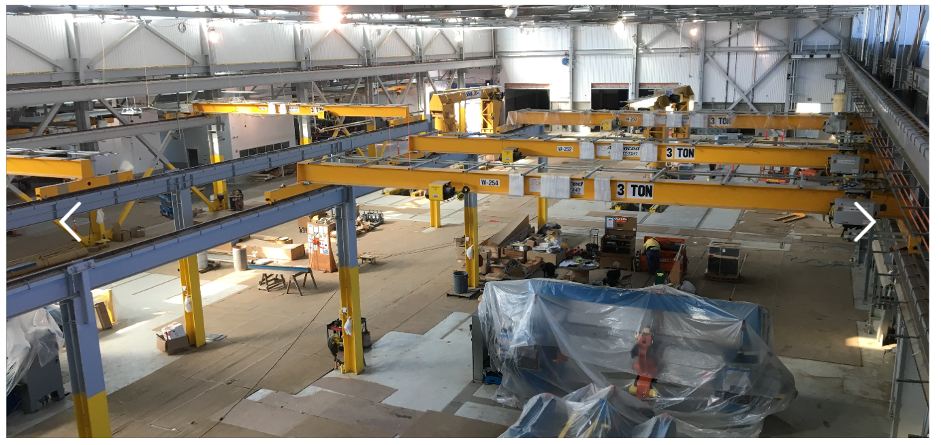

We had the opportunity to delve deeper into Omkar’s career and achievements during an exclusive interview. One of his key accomplishments that stood out was he developed a state-of-the-art estimation and design software. This tool proved invaluable for sales teams, enabling them to provide quick and accurate quotes to customers. This innovation reflects his ability to solve real-world business challenges through engineering acumen. Another significant achievement was during his tenure at Advanced Industrial Solutions, where he led the design of specialized overhead crane systems. Faced with the challenge of restricted vertical space, Omkar employed out-of-the-box thinking to create a unique low-connection profile with specialized notch girders and shear plate connections, transforming constraints into innovations.

More than his technical skills, Omkar’s talent for ensuring successful collaboration stands out, a feat that is not easily achieved in high-stakes, fast-paced environments. His commitment to continuous learning also means that he remains at the cutting edge of design engineering trends, adopting new technologies and methodologies to remain relevant in an ever-evolving industry landscape.

In essence, Omkar Sumbe embodies the future of design and engineering—adaptable, innovative, and dedicated to enhancing both functionality and human elements in the projects he leads. His tangible contributions to the crane design and broader engineering sectors set him apart as a trailblazer, continually pushing the boundaries of what is possible.

We’ve heard great things about your work, Omkar, and we’re excited to learn more about them. Can you walk us through the process of developing the estimation and design software? What challenges did you face, and how did it benefit the company?

During my tenure at my previous employer., I undertook the task of developing estimation and design software aimed at improving our internal processes. The objective was to expedite the creation of overhead crane drawings and facilitate the quick generation of accurate quotes. Leveraging my background in engineering and coding, I set out to achieve this.

A pivotal feature of the software was the inclusion of structural and hoist calculations. I integrated these calculations into the system via Excel sheets, ensuring that our designs met industry standards and local codes. To further enhance the software’s capabilities, I incorporated AutoCAD, which enabled the automatic generation of both preliminary and final shop drawings. This significantly cut down the time previously spent on manual drafting, thereby increasing overall efficiency.

Throughout the development process, I encountered several challenges that demanded innovative solutions. For instance, ensuring that the complex calculations adhered to different codes like AISC, CMAA, and ACI was crucial for maintaining safety and quality. Another obstacle was integrating the Excel sheets with the software interface, which I accomplished using Visual Basic coding. This required a deep understanding of both software development and engineering principles.

The software yielded substantial benefits for the employer. It revolutionized our workflow by automating the generation of overhead crane drawings, significantly reducing the risk of human error. Additionally, the software’s instant quote feature was a game-changer for our sales team, enabling prompt responses to client inquiries and thereby enhancing customer satisfaction.

In conclusion, the development of this estimation and design software was a fulfilling journey. The software not only streamlined our processes but also improved sales efficiency and customer satisfaction. By cleverly using AutoCAD and Visual Basic coding, we managed to integrate various aspects of design and estimation into a cohesive, automated system.

When leading design packages for overhead cranes at Advanced Industrial Solutions, how did you ensure that the designs met both technical specifications and client requirements?

At Advanced Industrial Solutions, when I’m in charge of leading design packages for overhead cranes, my top priority is ensuring that the designs meet both technical specifications and client needs. To accomplish this, I adopt a comprehensive approach characterized by clear communication and meticulous attention to detail.

The process starts with the creation of preliminary drawings, which serve as a visual guide to the proposed overhead crane design. These initial illustrations help clients visualize how the crane will integrate into their specific operational setting—its placement, range of motion, and overall functionality. This initial step lays a strong foundation for effective communication and collaboration.

Beyond these drawings, I offer clients a detailed quote that covers all the technical facets of the proposed design, from structural components to load-bearing capacities and safety features. Additionally, these quotes outline compliance with industry standards like AISC, CMAA, ACI, and applicable local codes. Presenting this information in a structured and understandable format allows clients to fully grasp the intricacies of the design.

Each client has unique operational needs and requirements. My focus is to tailor the design package to align with these specific conditions. This may involve tweaking the crane’s load capacity, adding special safety features, or incorporating other unique functionalities. Throughout this process, I work closely with the client to ensure that all their particular needs are addressed.

I consider client feedback to be an invaluable aspect of the design journey. I encourage an open dialogue and actively solicit input from clients. If there are suggestions for adjustments or modifications, I diligently incorporate them while preserving the technical integrity of the project. This iterative process ensures that the final design not only meets technical criteria but also aligns closely with the client’s vision.

To maintain transparency and collaboration throughout this process, I engage in regular discussions with the client, keeping them apprised of the design’s progress. This transparent approach fosters trust and enables real-time modifications, ensuring the final design meets all expectations.

In summary, my methodology for leading overhead crane design packages at Advanced Industrial Solutions encompasses clear communication through preliminary drawings, thorough technical quotes, customization in line with client requirements, and a steadfast commitment to collaborative transparency. By integrating these strategies, I guarantee that each design meets technical specifications while catering to the unique needs of the client.

Is there a particular project or accomplishment in your career that you’re especially proud of? Can you share the details and the impact it had?

In one specific project, I encountered the challenge of limited ceiling-to-floor dimensions. To address this, I designed a low connection profile, which included notch girders and shear plate connections to fit within the confined space. I also formulated an ingenious strategy using a shelf girder to navigate around an overhead obstruction.

Breaking away from traditional norms, I introduced a header-less crane system, a departure from the industry’s conventional header-braced systems. This innovative concept, unique to our company, has drawn considerable attention for its simplified installation and its capacity to handle heavier loads during lifting operations. This advancement represents a significant step forward in the crane sector, offering clients better functionality and performance capabilities.

In my role, I also manage the incorporation of fall protection systems, a vital feature that enhances workplace safety. This holistic design approach, focusing on both functionality and safety, demonstrates my steadfast commitment to delivering state-of-the-art and secure solutions. Additionally, I have a proven record of developing software that facilitates instant estimation and drawing generation. This tool has proven invaluable for sales personnel, allowing them to offer timely and accurate quotes to customers. This technological innovation not only streamlines the sales process but also boosts customer engagement.

How do you ensure successful collaboration within your teams, especially when working on pivotal projects like the ones you’ve led at Advanced Industrial Solutions?

Ensuring successful collaboration within my teams is a cornerstone of achieving excellence in projects, especially the critical ones I’ve led at Advanced Industrial Solutions. My approach to collaboration combines clear communication, shared goals, and a culture of mutual respect.

- Open Communication: I prioritize transparent dialogue within the team. By establishing clear avenues for sharing ideas, concerns, and progress updates, I ensure everyone is aligned. I encourage team members to voice their thoughts and take the time to actively listen to their contributions. This enhances project quality and fosters a sense of ownership among team members.

- Shared Goals and Vision: Aligning the team with clear project objectives and a shared vision is essential. I make sure everyone understands the broader goals and how their individual tasks contribute to the larger mission. This common purpose makes collaboration more seamless and focused.

- Utilizing Strengths: Recognizing and leveraging the unique skills of each team member is crucial. By assigning tasks that align with individual expertise and interests, I not only maximize efficiency but also empower team members. When people feel valued for their contributions, they are more inclined to collaborate effectively.

- Regular Check-ins: To monitor progress and tackle challenges, I arrange regular team meetings and check-ins. These sessions offer a platform for open discussions, question clarifications, and progress updates. They also allow me to provide timely guidance and support, ensuring the project remains on track.

- Problem-Solving Approach: Challenges are inevitable in any collaborative setting. I cultivate a problem-solving mentality within the team. When we encounter obstacles, we analyze the issue, brainstorm solutions, and collectively make informed decisions. This approach often yields innovative solutions and solidifies team cohesion.

- Recognition and Celebrations: Acknowledging milestones and collective efforts is important for maintaining team morale. I make it a point to celebrate successes, whether they are major achievements or small wins. This positive reinforcement cultivates a sense of camaraderie and motivates continued effective collaboration.

- Feedback Loop: Constructive feedback is key to growth and ongoing improvement. I foster an environment where team members are comfortable giving and receiving feedback. This two-way communication helps us identify areas for enhancement and encourages continuous learning within the team.

Can you describe a particularly challenging situation in one of your roles where you had to innovate or think out of the box to achieve a desired outcome?

Certainly! One particularly challenging situation that stands out occurred during my time at Advanced Industrial Solutions. We were tasked with designing an overhead crane system for a client who had extremely limited ceiling-to-floor dimensions. This presented a unique challenge that ruled out traditional design approaches. To solve this, I needed to think creatively and come up with an innovative solution.

I designed a low connection profile featuring specialized notch girders and shear plate connections. This approach allowed us to make optimal use of the limited vertical space without sacrificing structural integrity. Additionally, we faced another obstacle—an overhead obstruction that further complicated the design. To tackle this, I implemented a shelf girder configuration, ingeniously accommodating the obstruction while ensuring the crane remained functional and safe.

But the innovation didn’t end there. I saw an opportunity to introduce something entirely new to the crane industry—a header-less crane system, a departure from the traditional header-braced systems that are commonly used. This groundbreaking concept simplified the installation process and also allowed for higher lifting capacities. It garnered significant attention both within the company and in the broader industry.

Ultimately, my innovative thinking enabled us to deliver a highly successful solution that not only met the technical requirements but also exceeded the client’s expectations. This experience reinforced my conviction in the power of innovation and adaptability for overcoming challenges and advancing the fields of engineering and design.

After the implementation of the estimation and design software, were there any feedback or updates required? How did you handle the process of iteration and improvement?

After implementing the estimation and design software, I had the chance to present it to the internal sales team before leaving the company. Their feedback was invaluable for pinpointing areas needing improvement and refinement. They provided insights on various elements, such as dynamic pricing, sales tax considerations, and installation costs. This feedback highlighted real-world nuances of the sales process that I had not fully considered during the software’s initial development.

To address this feedback and make the necessary adjustments, I took a systematic approach to iteration and improvement. First, I reviewed the software’s codebase to grasp how the requested changes would affect existing functionalities. I then collaborated closely with the sales team to gather further information and clarify any ambiguities. This open dialogue helped me gain a clear understanding of their needs, enabling me to make informed updates to the software.

Specific changes included adjusting the pricing algorithms, accounting for sales tax, and refining the installation pricing module. Rigorous testing followed to ensure the modifications didn’t introduce any new issues or disruptions. After implementing the updates, I organized a follow-up session with the sales team to showcase the improvements and solicit further input.

The sales team’s positive response validated the effectiveness of the iterative process. While I had left the company before full implementation could take place, this approach ensured the software was better aligned with both immediate and long-term practical needs. The experience underscored the importance of collecting end-user feedback and iteratively improving the software based on real-world usage.

Building and delivering projects often require strong client relationships. Can you share an experience where maintaining a client relationship influenced the outcome of a project?

Sure. Maintaining robust client relationships has always been a cornerstone of my project management philosophy. This was particularly evident during a significant project at Advanced Industrial Solutions, where we were tasked with designing a complex fall protection system for a client in a highly regulated sector.

From the start, it was clear that the technical challenges were daunting and the client had specific, non-negotiable safety concerns that we had to address. Recognizing the importance of strong client relationships in this context, I committed to open, regular communication as a method for building trust and rapport.

We held frequent status meetings that served multiple purposes: they kept the client informed, allowed us to calibrate our mutual expectations, and gave us a venue for addressing concerns in real time. This proactive communication strategy was instrumental in not only keeping the client informed but also in reinforcing our commitment to the success of their project.

In the midst of the project, we encountered an unforeseen challenge when the client’s safety team raised concerns about an aspect of our initial design. Thankfully, our well-cultivated relationship with the client meant they felt comfortable bringing this issue directly to our attention. In response, I quickly organized an emergency meeting to delve into their concerns. Through a collaborative dialogue, we were able to understand their reservations fully.

This led to an alternative solution that satisfied their safety concerns while still adhering to regulatory standards. By keeping the lines of communication open and demonstrating a willingness to adapt, we were able to navigate this challenge effectively. The client felt heard and valued, which further solidified our relationship.

The project culminated successfully, meeting all the technical requirements and safety concerns. More importantly, it reinforced the client’s trust in our capabilities and commitment, laying the groundwork for future collaborations.

This experience underscored for me the immense value of maintaining strong client relationships. It showed that open communication, proactive engagement, and a collaborative spirit are not just supplemental to project success; they are integral components of it.

With the rapidly evolving nature of the crane industry and engineering tools, how do you ensure that your skills and the solutions you provide are cutting-edge and relevant?

In the rapidly evolving landscape of the crane industry and engineering tools, I prioritize continuous learning and staying abreast of industry advancements. This commitment ensures that both my skills and the solutions I offer remain cutting-edge and relevant.

Regularly reading industry publications, attending conferences, and participating in webinars and workshops keeps me informed about the latest trends, technologies, and innovations. This ongoing exposure to new ideas and practices equips me with up-to-date knowledge and tools.

I’m also committed to ongoing professional development. This includes acquiring relevant certifications, such as those in updated software, as well as attending advanced engineering courses and workshops. These experiences provide insights into cutting-edge design methodologies.

Engagement with peers, experts, and industry professionals is another crucial element of my approach. Through networking events and online forums, I exchange ideas, share experiences, and learn from others who are innovating in the crane sector.

Believing in the value of hands-on learning and experimentation, I often dedicate time to experiment with new tools, technologies, and approaches. Whether it’s creating prototypes or initiating mock projects, I explore the potential benefits and challenges of new solutions.

Collaboration with colleagues, both within my organization and across the industry, is indispensable. By sharing insights, experiences, and best practices, we foster a culture of continuous improvement and gain diverse perspectives on current trends.

I recognize that innovation is a continuous process. Hence, I remain open to change, willing to adopt new software tools, explore unconventional design approaches, or implement feedback from team members and clients.

Moreover, teaching and mentoring others also contribute to my own growth. Explaining concepts and solutions to others not only sharpens my own understanding but also keeps me current in my field.

In summary, my multi-faceted approach—comprising staying informed, pursuing professional development, networking, hands-on experimentation, collaboration, adaptability, and mentorship—ensures that I remain at the forefront of a rapidly evolving industry. This enables me to consistently deliver innovative and complex solutions to challenging problems.