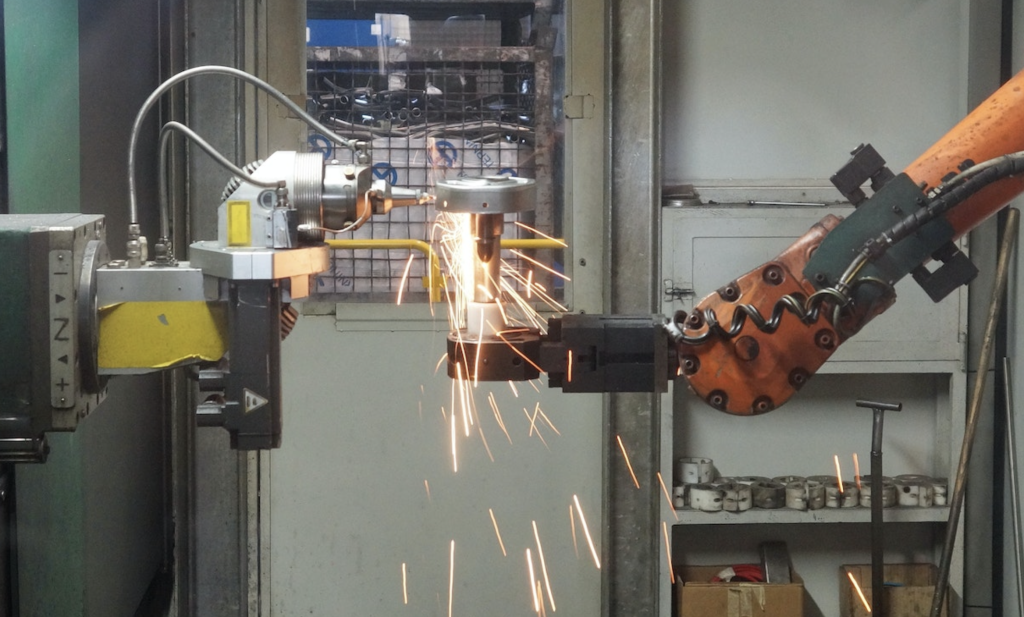

An automated mobile welding robot has become more popular recently thanks to its ability to offer a heightened productivity along with more precise results.

5 benefits of mobile welding robots

Whether you are thinking about investing in a singular robot or multiple, there are many benefits to implements mobile welding robots.

Some of these benefits include:

- Material conservation. Pre-programmed cuts are more exact and so lead to less waste, both materials and time. Because a mobile welding robot is able to continuously over an extended period of time, it uses less energy than starting up continuously. Welding errors become lessened thanks to increased accuracy via automation.

- As less waste of materials occur, clean-up time will become significantly reduced as well. You can expect to see less spattering’s and work built to achieve the satisfaction of your clientele time and time again.

- With every mobile welding robot that you invest in, you can see the returns. Reasons for this include a significant reduction in injuries that are produced by common hazards such as fumes, sparks and flash. A reduction in workers can also mean savings in wages, insurance and costs related to any accidents occurred.

- As outputs become faster and less mistakes, saving time in general is a theme that you will notice. Not only will productivity increase throughout the day, if you factor in the lack of vacation time and breaks, you can have a whole new slough of results.

- Faster adaptation of new and different projects will mean that you can get the welding results right away without having to factor in a significant amount of training or learning time. You can also achieve results completed with a high amount of precision.

While it may be an initially pricey investment, welding robots can add quality to your returns.